Project manager

Rapid, multilocational and cost-effective aerodynamic, vibrational and acoustic data capture on turbine blades

Civil structure designers and operators often struggle with capturing precise aerodynamic, vibrational, and acoustic data across their assets. Traditional methods either lack accuracy or are costly and intrusive.

Enter our solution: the first to simultaneously measure these parameters at multiple locations, rapidly and accurately. It's autonomous, simple, quick, and non-intrusive, offering a cost-effective way to optimize large-scale civil engineering structures. Experience the future of precision engineering today.

We are looking for a pilot project and manufacturing partners – get in touch if you are interested.

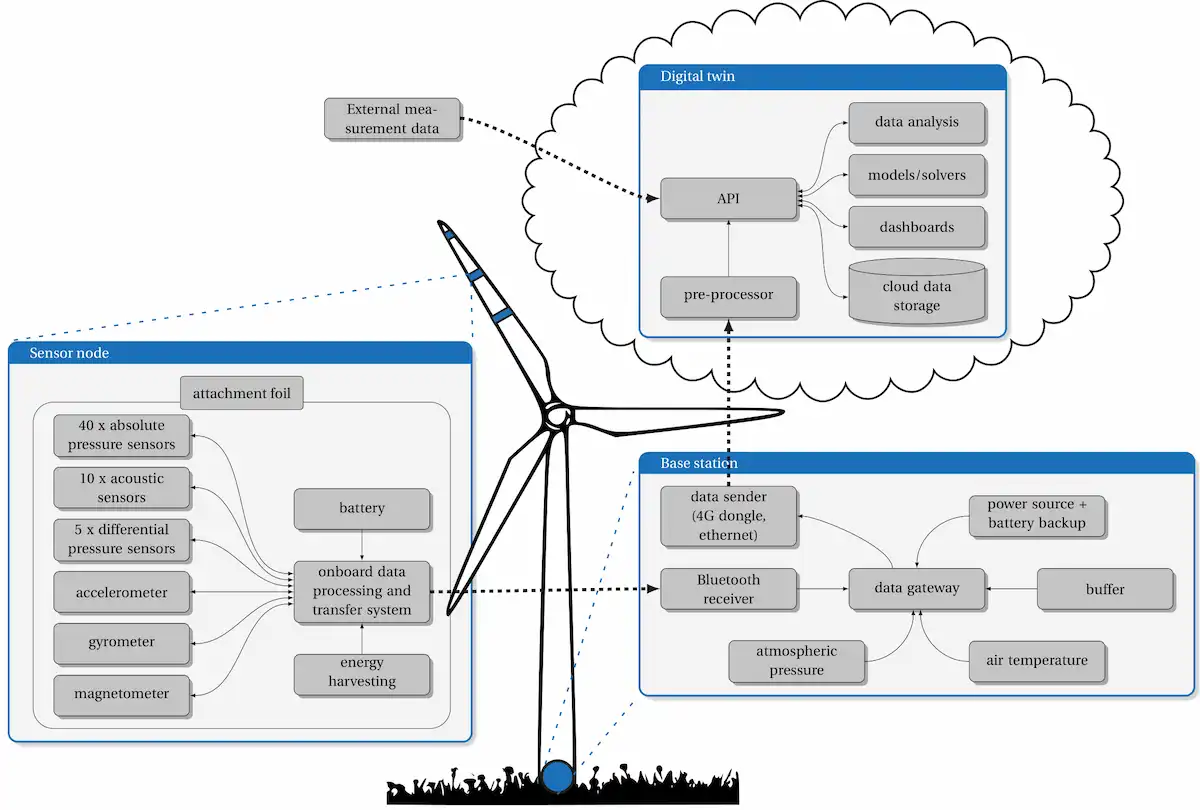

Modular, autonomous and heterogeneous multi-sensor node in one package

Low-power electronics, Bluetooth data transmission, and autonomous power management via a solar panel, all integrated into a thin 3D printed housing

Cloud-based digital twin with inverse and forward problem solvers to predict and infer relevant flow quantities

Integrated with the RTDT state-of-the-art suite of models and algorithms for structural monitoring & diagnostics

Can be distributed along the span of the blade in an autonomous, easy, quick, non-intrusive and cost-effective unit

Simply glue the Aerosense node on the external surface of the wind turbine blade, and it is good to go

Absolute aerodynamic surface pressure from 40 barometers for each blade section

Differential pressure at the leading edge from 5 differential pressure sensors

Vibrations from a 6-DOF IMU unit

Blade surface temperature

Acoustics from embedded microphones at the trailing edge

Sampling rate: 100Hz (kHz range is possible for microphones and differential pressure sensors)

Cut down on high costs and limited data from traditional inspection methods. With Aerosense, there's no more reliance on drone-based inspections (~500 CHF per flight per turbine) or rope access inspections (~3000 CHF per turbine per day). Forget about the limitations of embedded fiber optic strain sensors that only measure strain and are too expensive.

Aerosense offers the potential to replace nacelle-mounted Lidar systems for wind inflow characterization on the rotor plane. Our unique selling point? Aerosense enables users to access a wide range of aerodynamic and structural monitoring and diagnostic use cases for wind turbine blades. All from a single low-energy, wireless, non-intrusive multi-sensor node. Choose Aerosense. Choose efficiency.

01

Deliver and display measurement data from the wind turbine on the dashboard

02

Assess sound pressure levels and infer the angle of attack from measurement data

03

A separate simulation framework trains ML models for classifying LEE.

04

Various models can be applied directly to aerodynamic pressure time series data to detect structural faults

05

For a snapshot of the pressure distribution around an airfoil, determine the surrounding steady pressure and velocity fields. At the same time, determine free stream conditions (velocity, turbulence, AoA)

Aerosense is based on the technology developed within the BRIDGE Discovery project «Aerosense»*, which finished on 30.04.2023. The project was lead by Sarah Barber at the Eastern Switzerland University of Applied Sciences (OST), one of our Scientific Advisory Board members.

The RTDT software supports owners, operators, service providers and OEMs throughout their journey into monitoring and diagnostics for more reliable and profitable wind turbine fleet

We conduct fundamental, long-term R&D toward the creation of safe and reliable wind turbines